On Demand 3D Printing

Bring your ideas to life.

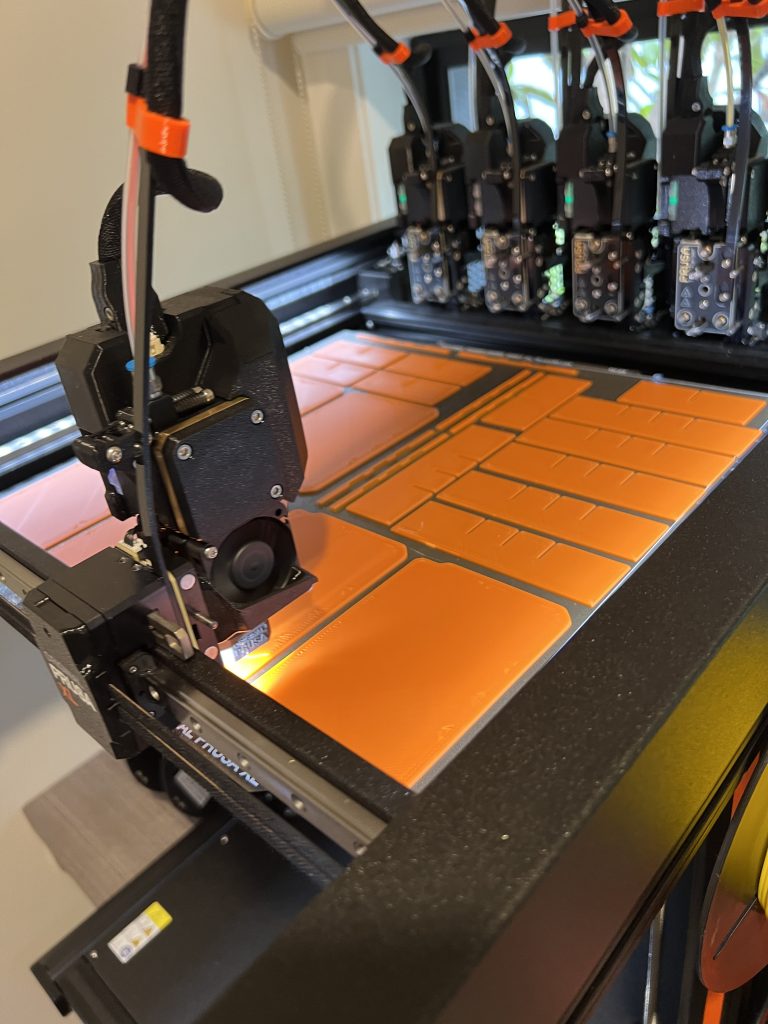

Printing just a few?

If you are looking to prototype or manufacture in low volumes, 3D printing can be your perfect solution.

3D Printed parts can be as strong as traditionally manufactured, ready for production.

Additive manufacturing is the future – Join the revolution!

Have an idea in mind?

Let’s make it real.

From Imagination to Reality

- 3D Printing

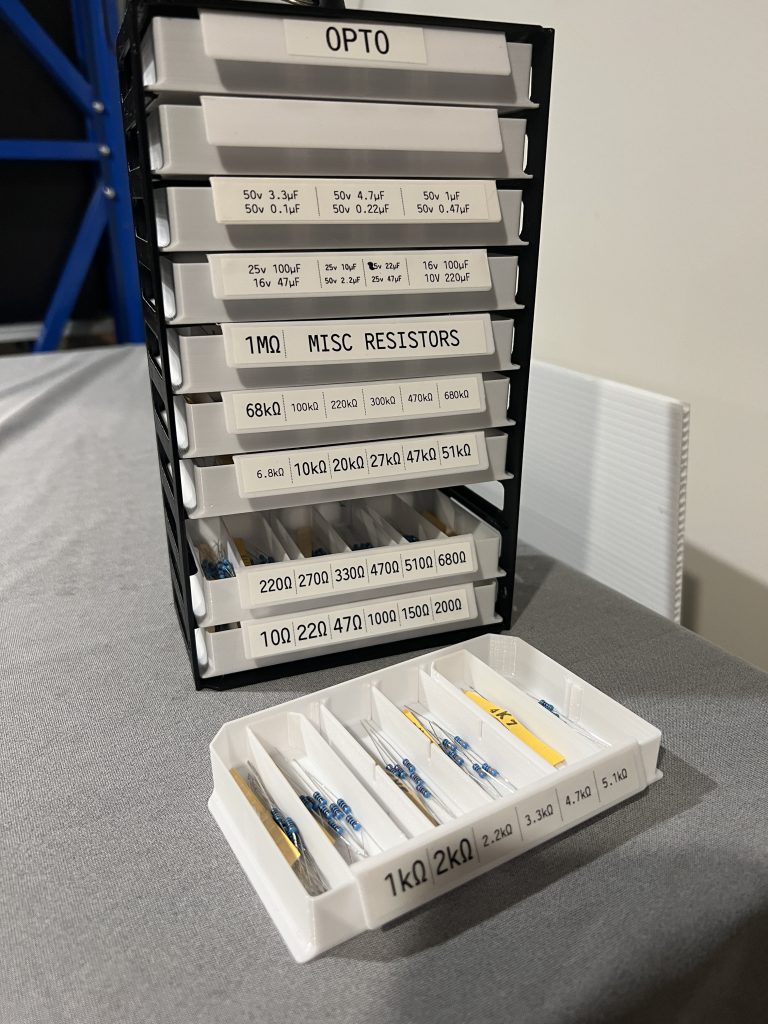

Available FDM Materials

PLA

Rapid Prototyping King.

PETG

Excellent “all-rounder” material.

CF-PLA / CF-PETG

Super Strong

Others

Please enquire!

We are constantly testing new filaments and improving techniques so if you have a special request, do not hesitate and enquire!

Thinking of your next prototype?

Need help with the design?

Whether you need to design a product from scratch, create a replacement part for an existing one, we’re here to help.

Frequently Asked Questions

3D Printed parts can be VERY strong – According to the material and printing technique used, 3D printed parts can be as strong as Aluminium.

Some printers can also create metal parts, which after processing, are almost indistinguishable from a traditionally manufactured one.

Currently, our maximum volume is 360x360x360mm for a single part. Larger prints can be achieved by combining multiple parts together by either mechanical locks, screws or simply gluing parts together.

Printing times vary according to part complexity, requirement of supports, printer settings, number of items per batch, and number of batches.

While printing at a height of 0.3mm per layer, a small part can take as little as 10 or 20 minutes, while printing a larger object at higher resolutions like 0.07mm per layer can take hours or even days.

Although we strive to optimise printing times, certain sacrifices are sometimes required the ensure the items print correctly. Every object is treated uniquely, as their optimisation will be different from another object or part, ensuring that it’s printed using the correct settings.

Printing batches do carry certain risk, as sometimes due to unpredictable factors some prints can actually go wrong, potentially losing just one object, or worse the whole batch. If the batch is large, then so is the loss of time and material. To prevent this, an appropriate optimisation between batch size and printing requirements is carried on for every project, so you can rest assured that your prints will come as required.When you send us your files, we will respond with a full cost and time estimate.

Great question.

Selecting a material is a crucial part for 3D printing. If your print will be subject to mechanical stresses, we would suggest looking at Nylon or ASA or carbon fibre (CF) reinforced filaments.

These materials are great for functional parts. Slight differences in materials still need to be considered. For example, while carbon fibre reinforced PLA can be stronger than regular PLA, it normally makes it slightly more brittle, meaning that for a part that would require flexing would not be recommended but, for a part that will be either compressed or stretched in line with the grain, then it might be the perfect choice.

If you’re looking for a prototype, regular PLA and PETG are excellent low-cost alternatives that can still yield amazing results. While these filaments can also print functional parts, they are very popular with makers for mid-to-low stress functional prints.

When in doubt, give us a shout!

Our colour and materials stocks varies according demand and market availability. If you want it and we don’t have in stock, don’t worry! – We’ll hunt it down for you.

At the moment our multi-material capabilities are restricted. A single object with multiple materials is not very common to do and special attention would be required around the adherence and interfacing of each material.

Some other techniques that currently exist generate a ton of waste which we try to avoid, as it unnecessarily bloats the costs while creating plastic pollution.

We can always try to address and accommodate these requirements. However, from experience is often best to design individual parts that can be printed in different materials for later assembly.

Short answer: Yes.

Is there a catch? — it depends.

Multi-colour prints often require that the printer changes filament amid layer or between layers in order to achieve the desired effect. While some printers do this automatically, they create a “wipe tower”, which is just a small tower of wasted filament that is created when the printer is purging the nozzle to transition from one colour to another.

Some techniques try to minimise this, but any colour change will inevitably create wastage, so the more colour changes you would have on a print, the more waste and the less efficient the whole print becomes, so cost efficiency or “bang for the buck” can be greatly impacted.

If your multi-colour print can be done in parts, it is much more efficient to do it like that, as each part will be printed with near-zero wastage, but with the trade-off that then it’s necessary to assemble things together.